For: LABELS | FILM & FOIL | LIGHT PACKAGING | SPECIALITY PACKAGING

For: LABELS | FILM & FOIL | LIGHT PACKAGING | SPECIALITY PACKAGING

World-class technology, endless versatility.

Designed from the ground up for label production. We can support your demand

no matter the size of the print run. Download our brochure now or contact us today.

The most versatile single-pass Label Press you've ever seen.

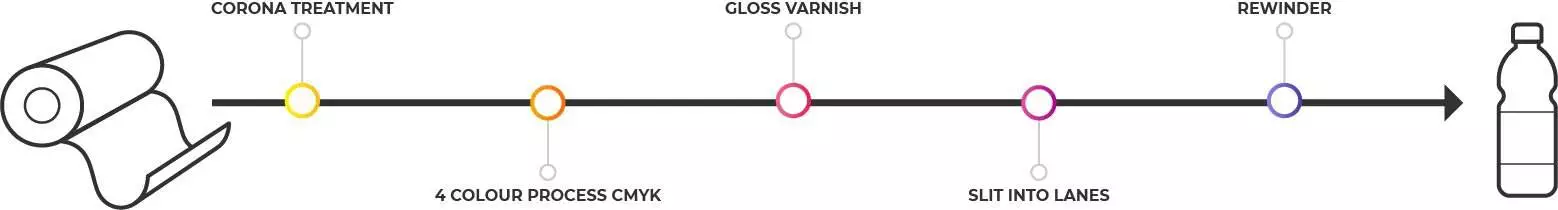

This Label has been produced in a single pass using the Edale FL3 Label press.

Corona treatment

Substrate surface to be fully prepare for printing and ensuring excellent ink adhesion.

4 colour CMYK process

Achieved by Edale’s fully servo driven design and unique print head geometry (Uniprint). This ensures unrivalled registration accuracy which allows for easy use of process printing without spot colours.

Gloss Varnish

Gives a high end look to the product whilst also offering protection to the printed label.

Slit in lanes

A fully automated or manual set slitting system within the press allows for product to be easily slit into finished product and to remove any edge trim that is not required.

Rewound on Slitter Rewind

Individual slit lanes are rewound onto a single shaft or optionally onto two differential shafts to give distinct smaller reels for easier removal.

From raw material to finished label in 1 minute!

ALL IN A SINGLE PASS

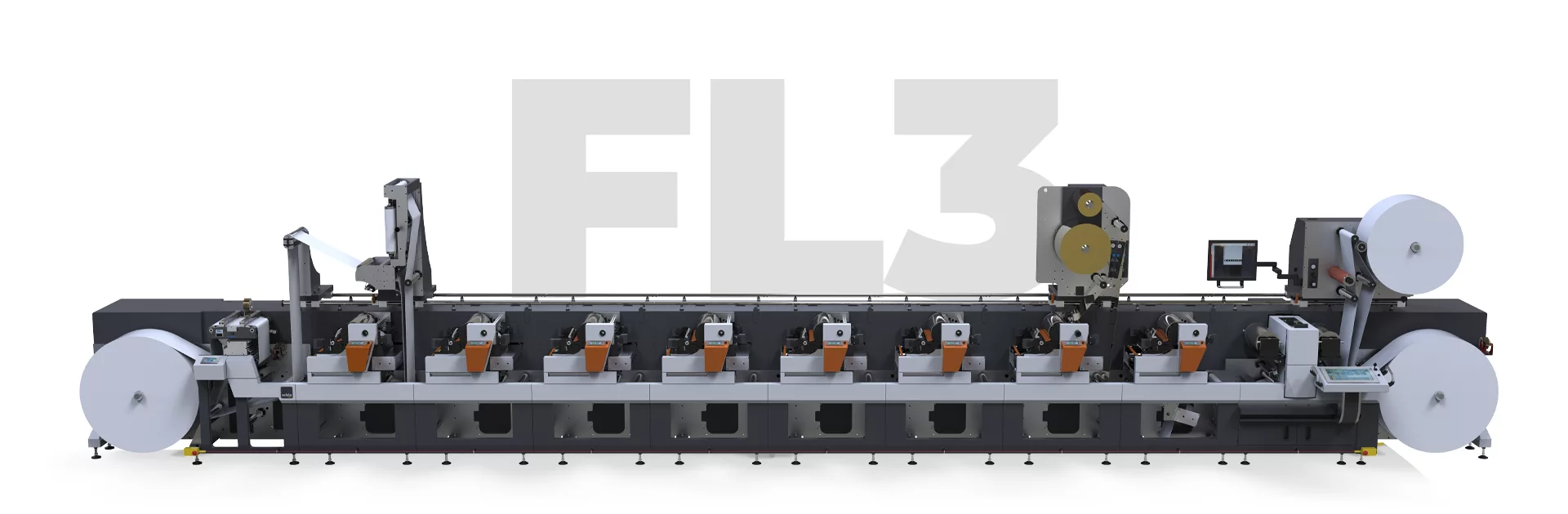

Discover ourFL3 Label Press

A highly productive, cost-efficient, quality label and packaging printing press.

FL3 - Highly productive, cost-efficient, quality label and packaging printing press

Completely modular in design and fully servo-driven makes FL3 as the best label printer system & the ideal choice for any business. The seven motors on each print station as standard plus a magnitude of finishing options allows a level of performance and customisation that fits each individual customer requirements. The enhanced HMI capabilities make the FL3 the best label printer system which is highly efficient, whilst enhancing the operator experience and reporting capabilities.

Autonomous inking impression and registration (AiiR) settings can be stored into the HMI making job recall and repeatability simple for the operator resulting in less waste, less set-up time and lower rejects. The FL3 is designed for easy operator use and combined with Edale “Uniprint” unique print head geometry allows ultimate print quality to be easily achieved.

The FL3 has the most extensive standard substrate range of any press on the market, 12-450 microns, allowing the printer to handle many different substrates including, film, labels, shrink sleeves, lamitubes, foil and light cartons to name but a few without any additions or alterations to the press.

Designed to be future proof, the fully modular build can easily be upgraded with either more embellishment tools or extra printing stations, either analogue or digital.

The in-house mechanical, electrical and software capabilities allows for ultimate reliability whilst maintain the customisation philosophy to give you the perfect press for your business both now and in the future.

Product Technical Specifications

| Product | FL1 PRIME | FL3 | FL5 | FL7 |

|---|---|---|---|---|

| Web widths (inch) (mm) | 350mm | 13.7” | 430mm | 16.9” | 600mm | 23.6” | 650mm | 25.5” 760mm | 29.9” 850mm | 33.4” |

| Repeat range (inch) | 8 – 24” 203.2 – 609.6mm | 8 – 24” 203.2 – 609.6mm | 10 – 28” 254 – 711.2mm | 14 – 36” 355 – 914mm |

| Material range (micron) | 12 – 350 microns 0.5 – 14pt | 12 – 450 microns 0.5 – 18pt | 12 – 700 microns 0.5 – 27pt | <700 microns <27pt |

| Mechanical speed (m/min) | 200 m/min | 660 ft/min | 200 m/min | 660 ft/min | 200 m/min | 660 ft/min | 300 m/min | 990 ft/min |

The best of everything as standard

Our focus is on quality engineering, and all our presses include the latest technology as standard.

Shaftless dual servo print technology

Genuine full servo shaftless independent drive technology ensures print precision and consistency.

Gearless Impression

No gear mesh so guarantees exceptional print quality and a wide substrate range

Automatic Registration

Ensures register precision and consistent print quality.

UniPrint

Consistent, high-quality print, whatever the repeat size

Job Storage / Job Recall HMI

Unlimited job storage, saves and recalls all job specific machine settings and job production data.

Set & Forget Impression

Automatically set Anilox-to-Plate Impression ensures uniform ink coverage across the plate without over impressing.

On-the-fly setup

Colour changes whilst you are still in production.

Pre-register

Automatically positions the print cylinder in the correct position based on job recall.

Short web path

Minimises waste and maximises efficiency.

Aiir

AiiR stands for Autonomous inking, impression and register. It is Edale's own technology designed to automate the process, reducing the reliance on the operator to set and regulate.

EZ Reg

Fully autonomous camera register system controls linear and lateral register without any operator intervention.

Electronic linear and lateral register

Electronic positioning of linear and lateral register prepares the machine for EZ REG upgrade.

Discover ourFL3 Label Press

A highly productive, cost-efficient, quality label and packaging printing press.

Unrivalled customisable options to take your press to the next level

Our presses are tailormade to suit your needs with options available to future proof and evolve your press to suit your customers' needs.

EZ Reg

Fully autonomous camera register system controls linear and lateral register without any operator intervention.

EZ Die

Die-cut change in under 60 seconds, pre-register linear and lateral pre-register and automatic waste pick-up.

EZ Matrix

Combination contact and non contact waste stripping.

VLS Sheeter

Electronic setting of sheet and perforation length negates the need for multiple sets of tools.

Label Pack

Rail mounted delam/relam, Turnbar, cold foil and lamination for label embellishment.

Film Pack

Corona treatment, web cleaning, chill rollers and roll follower for unsupported film production.

Eco Pack

LED curing technology reduces total power consumption by up to 75%.

Finishing Automation Pack

Semi-rotary die-cutting, auto set slitting and autoset back slitting fully automate the label finishing process.

Multi-layer Printing

Single-pass, two and three ply peel and read label production.

Hybrid Printing

Combining the best of analogue and inkjet print technologies for short and medium run efficiencies.

FULL ROTARY DIE CUTTING

Heavy duty servo driven rotary die cut station.

HOT FOIL STATION

Rotary Hot foiling station. We can also offer Big FOOT or Pantec for Hot foil.

FDC 600

Web fed Flatbed die cutting for cartons.

AVT INSPECTION & REGISTRATION CONTROL

Pressure validation & 100% Inspection.

CROSSOVER

Single pass two and three ply peel and read label production.

Increase workflow with our range of Print Room Ancillaries

We have a range of print room ancillaries to support your print operation.

EZ Mount Plate Mounter

The EZ Mount ensures correct, accurate mounting, easy pre-reg, giving consistency and high quality print.

EZ Cart

Additional cart for EZ DIE magnetic die tools.

Anilox Cleaner

Ultra-sonic anilox cleaning.

Plate Cutter

Quick and accurate cutting of plates prior to mounting.

AUTOMATIC SPLICER & NON-STOP REWIND

Add up to significantly increased productivity, greater quality control and reduced waste.

EZ Bench

Storage for up to 4 EZ DIE magnetic die tools.

EZ Slitter

Label slitter rewind and inspection machine.

Plate Cleaner

Plate washing prior to storage.

News &Case Studies

We believe that the most powerful story comes from our customers, and we will be sharing these with you. To keep up to date with news and stories – follow us on LinkedIn.

Press Release

Label Pack Morocco invest in an Edale FL3

Based in Casablanca Morocco, Label Pack has selected the Edale FL3 as their next press investment.

The new FL3 is 430mm wide and has 6 print stations and also hosts Edale’s latest technology “EZ Reg” which is an automatic register set up and continuous register monitoring in X and Y direction. The press will be predominately used for labels and flexible packaging.

Press Release

Kingfisher buy second Edale FL3 making it their 8th Edale press

Kingfisher Labels based in Yate, North Bristol have invested in yet another Edale Label press.

The second Edale FL3 is due to be installed in the first quarter of 2019 and comes less than 3 months from the first FL3 install. The 6 colour, 350mm wide press specified for high quality labels and will assist Kingfisher in their continued growth.

Press Release

iTek Packz opts for second Edale Flexo Press

Based in Bangalore India, iTek Packz has chosen Edale as their preferred machinery partner.

Their latest investment is a new 9 colour Edale FL3, 430mm wide suitable for the production of high quality labels. The FL3 boasts an array of options including Edale’s latest innovation the EZ Die, which is a quick change full rotary die cutting system that allows the user to change a tool in less than 60 seconds.

Edale offer the best combination of suitable technology, a knowledgeable team and synergy with Amberley’s requirements.Amberley Adhesive Labels

Experience the difference Edale can make

If you are considering buying from us, or interested in some form of commercial partnership or simply want to find out more, please drop us a line using the form and we will be in contact shortly.