Case Study | FL3

FL3 Flexo Press Printing For Integrity

As UK based Integrity Print set about adapting their business model to focus more on labels where there are more opportunities for growth, the company who have three production units looked to expand their capabilities with the aid of an FL3 flexo press printing machine.

Solution

After meeting with the customer, Edale were able to recommend the FL3 as the ideal press to help them grow the filmic side of their business, at a budget which suited them.

Having three production units in operation, the make ready and set up times of this cost efficient press were crucial to this fast paced company.

Benefit

The new eight-colour press can print conventional flexo or UV. It has fast make ready times, with job changeovers possible in just 70 seconds, and can handle substrates from 12-450 microns.

The investment in equipment looks set to be returned through sales within the next year or so if business continues to grow as it has been.

We will be able to offer our customers a lot more options. Demand for self-cling and filmic labels is growing, and the FL-3 allows us to print onto a really good range of substrates, including thin film packaging

— Dave Meredith, Label sales manager, Integrity

View More Case Studies

November 13, 2024

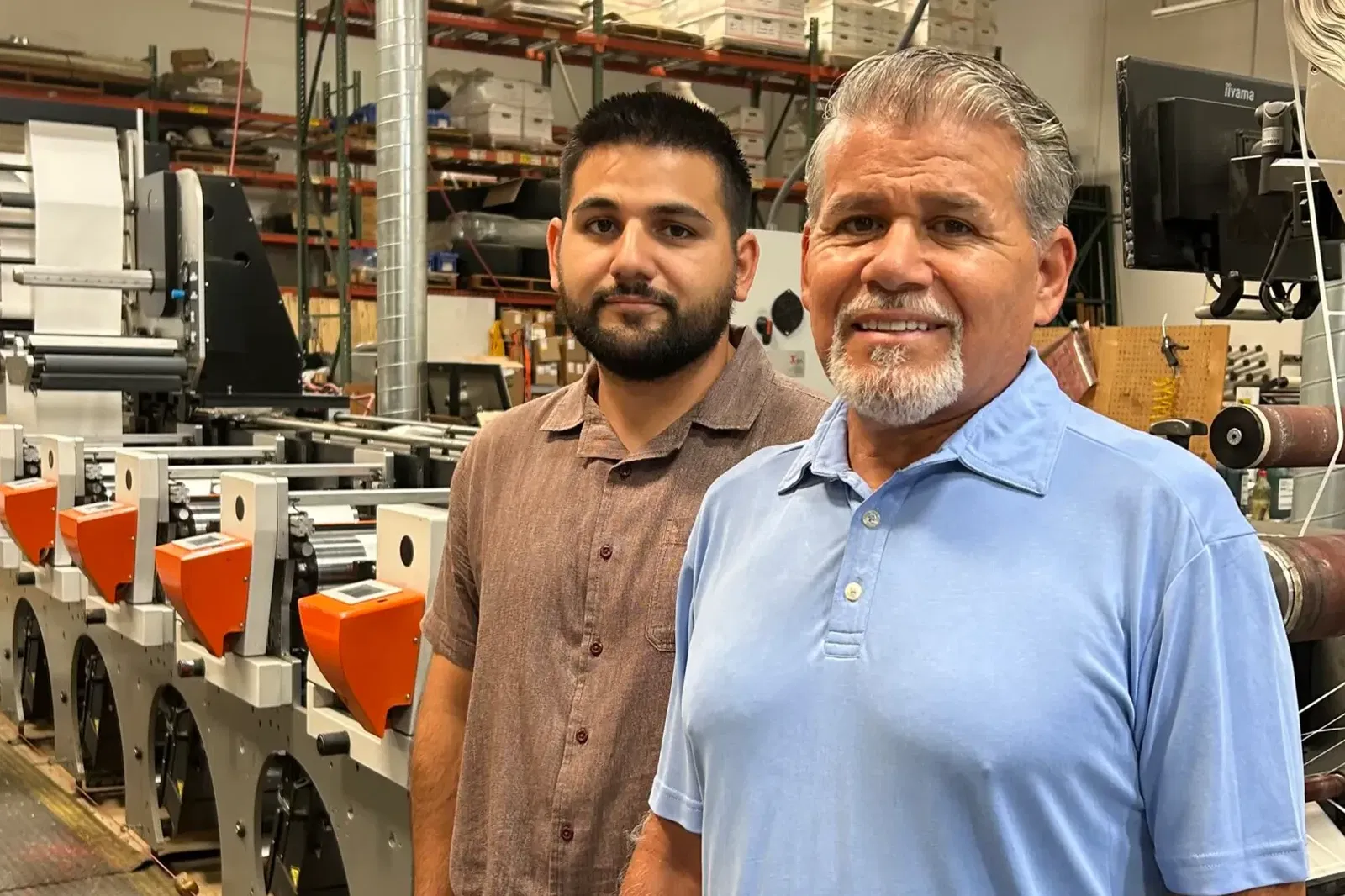

The Edale Experience: GEO LABELS, INC.

"As it becomes more difficult to find skilled press operators in today's workforce, presses need to be intuitive and fast."

January 17, 2024

PDQ Label Printing – Case Study

PDQ are a labels and flexible packaging printing company and leading provider of high-quality printing services to clients all over Australia. With years of experience in the industry, they have…

June 13, 2022

Reelvision Print

Lancashire (UK) based company, Reelvision, manufacture for and supply to, the pharmaceutical, healthcare, personal care and FMCG carton market. Having purchased their first FL5 Carton Production Line…

June 8, 2022

Folding Carton Publication – FIRST EDALE CARTON PRESS IN THE USA

– NICK COOMBES REPORTS FROM THE COMPANY’S HEADQUARTERS IN FAREHAM, HAMPSHIRE.

May 26, 2022

DPI Direct

DPI Direct have a state-of-the-art facility in San Diego and specialise in digital and offset printing, custom packaging and labels, direct mail, and wide format.

January 28, 2022

Interview with New York Label & Box Works – The first US Company to invest in Edale’s FL5 Technology

Interview with Steven Haedrich, Presiden of New York Label & Box Works the first USA customer to install one of our FL5 carton production lines.

August 2, 2017

ProPrint Group

ProPrint are a BRC-approved (British Retail Consortium) company offering a full in-house concept-design-production facility with a strong reputation for its fast-response, ‘no fail’ service.

August 2, 2017

Flexible Technologies

Flexible Technologies LLC required a solution for their go-to market digital flexible packaging strategy.

August 2, 2017

Amberley Adhesive Labels

Amberley have established a reputation as one of the UK’s premier label production companies and have developed packaging for an extensive range of sectors including cosmetics, personal care,…

August 2, 2017

MPH Fulfilment

UK label production company MPH Fulfilment produce a wide variety of packaging solutions for numerous industries. They have recently purchased their sixth Edale press, suitable for the production of…

August 1, 2017

Demax Graphic Arts Group

Bulgarian print group Demax has cut lottery scratch card printing from three weeks to just two days with a ‘total solution’ Edale 17-colour web press, featuring inline personalisation and Edale’s…

March 31, 2017

Telecom Company

A telecom company based in the UAE approached Edale to help them with a high specification print and personalisation line to help them produce high volumes of telecom recharge cards whilst adhering…

Experience the difference Edale can make

If you are considering buying from us, or interested in some form of commercial partnership or simply want to find out more, please drop us a line using the form and we will be in contact shortly.