MOBILE/TABLET VERSION STARTS HERE

WEB-FED FLATBED DIE CUTTING

FOR CARTONS

MOBILE/TABLET VERSION ENDS HERE

The most versatile single-pass Carton Press you've ever seen.

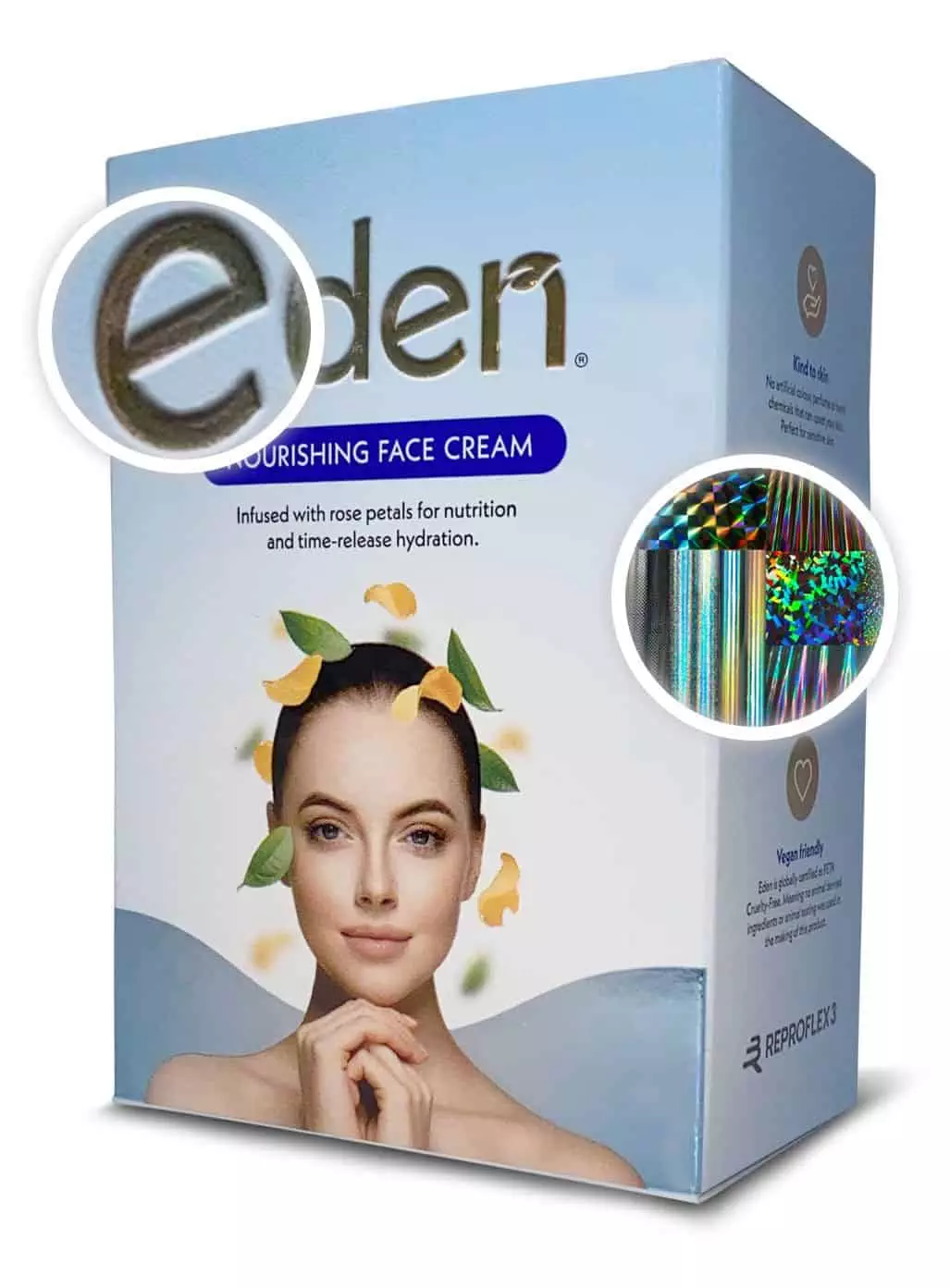

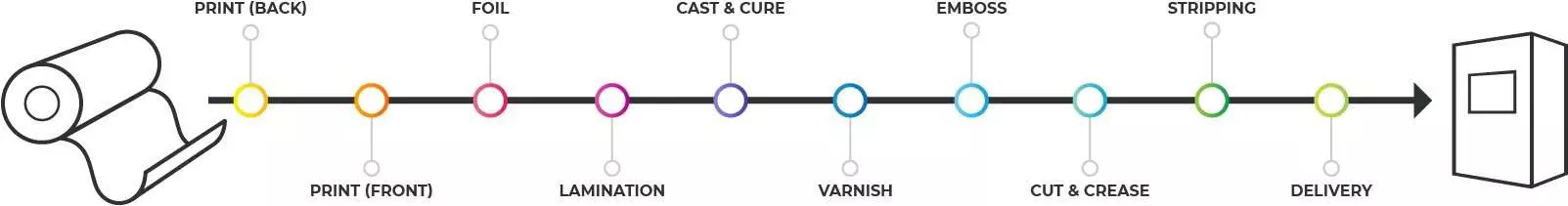

This carton has been produced in a single pass using the Edale FL5, 510mm with inline (FDC) Flatbed Die Cutter.

Cold Foil

has been laminated on the FL5 Prime full width to give the effect of more costly Met PET cartons.

Embossing

is added inline on the FDC to give a 3D tactile effect.

Unique Uniprint

Colours are printed using Edales unique Uniprint print head to ensure the best possible quality.

AiiR System

(Autonomous Inking Impression and Registration) on the FL5 gives unparalleled automation and repeatability of quality and print accuracy.

Cast & Cure

has been added to give a finish that adds brand protection and allows the carton to really stand out from other production methods.

Cut, Creased & Stripped

The carton was finally cut, creased and stripped before being discharged onto a conveyor by the FDC 600.

From raw material to finished carton in 1 minute!

ALL IN A SINGLE PASS

Interested in the FL5?Why not book a demo?

Come and join us on a virtual demo to see the FL5 Flexographic single-pass carton press

The FDC-600 gives you all the efficiency of a reel fed system and the benefits of flatbed die technology & versatility.

Do you want to eliminate your work in progress, reduce the number of operators, waste and power, and give an unrivalled delivery time to potential customers?

The Edale FDC-600 flatbed die-cutting machine combines the best of sheetfed flatbed die-cutting technology with a cutting-edge servo-driven constant tension web transport system. Specifically designed for fast job change and setup when run in-line with flexo systems or digital lines, the FDC-600 creates a highly efficient web-fed, single-pass folding carton production line.

With a maximum speed of 13,000 impressions per hour, the ability to nest products up to four, pre-registration and the benefit of being able to reconfigure the machine for a wide range of carton sizes and forms without specialist tooling ensures that downtime and substrate wastage is kept to a minimum.

The FDC-600 flatbed die-cutting machine can be retrofitted to an existing Edale, or other manufacturers press or to a roll stand for off-line conversion of analogue or digitally pre-printed webs.

The machine will perform well with a wide range of carton board thicknesses up to 700 microns.

Products can include cutting, creasing, embossing and brail, with delivery being done with a de-nesting system that will ensure easy collection.

A range of other delivery solutions such as a stand-alone Jumbo Unwind and side unloading conveyors and batch stackers are also available.

FDC-600 Flatbed Die-Cutting Machine GIVES YOU:

- Improved efficiency

- Single-pass

- Quick die changeover

- Industry accepted die-cut quality

- Proven web fed technology

- Adapts to a wide range of carton sizes

- Use with an Edale FL press or ability to interface with existing presses

- Inline or standalone capability

The best of everything as standard

Our focus is on quality engineering, and all our presses include the latest technology as standard.

Pre-register

Automatically positions the print cylinder in the correct position based on job recall.

Continuous Web Infeed

165 tons cut pressure | 120 tons cut pressure

Quick Release Chase

De-nesting

Waste Stripping and Chopping

Waste Transfer Conveyor

Unrivalled customisable options to take your press to the next level

Our presses are tailormade to suit your needs with options available to future proof and evolve your press to suit your customers' needs.

Jumbo Unwind for off-line operation

1.5m (60" ) Jumbo unwind with optional 2", 6" & 12" mandrel and reel lift with touch screen control.

Automatic batch stacker

Increase workflow with our range of Print Room Ancillaries

We have a range of print room ancillaries to support your print operation.

EZ Mount Plate Mounter

The EZ Mount ensures correct, accurate mounting, easy pre-reg, giving consistency and high quality print.

EZ Cart

Additional cart for EZ DIE magnetic die tools.

Anilox Cleaner

Ultra-sonic anilox cleaning.

Plate Cutter

Quick and accurate cutting of plates prior to mounting.

EZ Bench

Storage for up to 4 EZ DIE magnetic die tools.

EZ Slitter

Label slitter rewind and inspection machine.

Plate Cleaner

Plate washing prior to storage.

News &Case Studies

We believe that the most powerful story comes from our customers, and we will be sharing these with you. To keep up to date with news and stories – follow us on LinkedIn.

Press Release

Reelvision Invest in their third Edale single-pass Flexographic Carton Line

Edale is proud to announce that Reelvision, manufacturers of Pharmaceutical, Healthcare, Personal Care and FMCG cartons have invested in an FL5, single-pass printing and converting carton line, comprising of 8 colours, 540mm width and an FDC 600 web-fed flatbed die-cutter to join their existing Edale machinery.

Press Release

Imprimerie Ideale opt for second FL5 from Edale

Based in Casablanca Morocco, Imprimerie Ideale have chosen Edale as their preferred machinery supplier for a second time, this follows on from their initial purchase of an 8 colour Edale FL5 with Flatbed die cutter.

Their latest machine is a 510mm wide, 8 colour FL5 equipped with a screen module as well as a rotary die station for inline die cutting, embossing and sheeting.

Press Release

Three Gold Awards in a row

iTek Packz is known for its awards for Excellence in Flexography and Innovation, and for the third-consecutive year running has been awarded gold for Flexography, Narrow Web and they also received the highly acclaimed ‘Best in Show Award.’

They have been given high praise from the FTA judges for their winning entry, for Narrow Web, process, paperboard, which was a vibrant soap carton.

Managing Director, Gareth Bakewell, Reelvision comments: “Our investment in the FL5 carton press will be a great addition to our existing Edale machinery. We have worked with Edale on a number of specialist projects now, and our priority is to ensure that as we continue to grow, we stay ahead of the curve through our continued investment in the very latest new future-proofed technology to ensure we bring our customers the best possible packaging solutions.”

Experience the difference Edale can make

If you are considering buying from us, or interested in some form of commercial partnership or simply want to find out more, please drop us a line using the form and we will be in contact shortly.

Product Technical Specifications

| FDC | |

|---|---|

| Web width | 600mm | 23.6” |

| Maximum cut length | 711.2mm | 28" |

| Maxium cut width | Equal to max web width |

| Height of cutting blades | 23.8mm |

| Maximum cutting force | 165 Tons |

| Maximum diverging card delivery | 4 across |

| Impressions | Up to 13,000 per Hour |