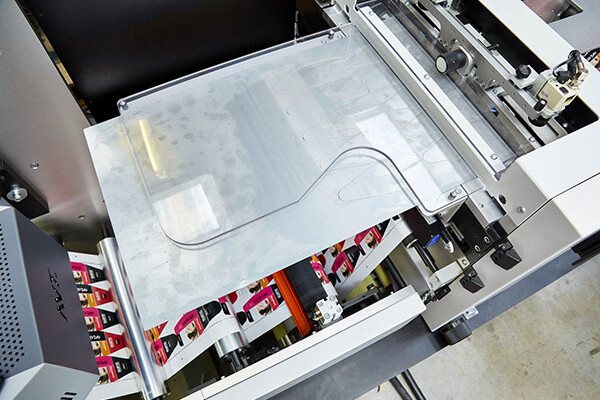

Autoset Back Slitter

A HIGHER LEVEL OF ACCURACY

Continuing our series of short videos showing the many time and money-saving technologies and features on the FL3 Flexographic Label Press we present to you the Back Slitter with Autoset.

At the touch of a button the Autoset Back Slitter quickly sets the blades into exact positions. Blade positions are loaded from the job storage database or via the HMI and placed accurately first time, eliminating any human error.

This also makes the unit safer as the operator doesn’t need to touch the blades when moving them and can repeat exactly where the blades are located.

Cutting-edge technology!

Slitting

- Automatic movement of the knives

- Uses job storage for moving location to location

- Position can be inputted manually if needed or for fresh job

The Benefits

- Quick, accurate and repeatable setting of blade positions

- Safe operation

- Simplifies setup

- Saves time

All our technology can be optimized for your application

View More Converting Technologies

Rotary Die Cutting

In full rotary mode, it will operate up to full press speed, subject to application. This full rotary mode still has a pre-register feature, utilising the information from the Job Storage which is…

Semi-rotary Die Cutting

In semi-rotary mode, the magnetic die does not need to change when moving from one format size to another. It can operate like this at speeds of up to 65m/min. This reduces downtime between each job…

Flatbed Die Cutting

The FDC-600 can be retrofitted to an existing Edale, or other manufacturers press or to a roll stand for off-line conversion of analogue or digitally pre-printed webs. The machine will perform well…

Autoset Sheer Slitter

Cutting edge technology! This fully automated "pick and place" system quickly positions up to 15 slitter knives in a fraction of the time compared to a traditional slitter. Knife positions are loaded…