The Edale Experience: GEO LABELS, INC.

Article attributed to Greg Hrinya at Label & Narrow Web.

The label printing industry is known for being highly dynamic and fast-moving; staying one step ahead often means embracing new technologies that center on productivity, quality, and versatility.

For Geo Labels, Inc. (‘Geo Labels’), a well-established and respected label converter based in Ontario, CA, USA, the decision to invest in an Edale FL3 flexographic press has proven to be a game-changer, reshaping their production capabilities and positioning them for future growth.

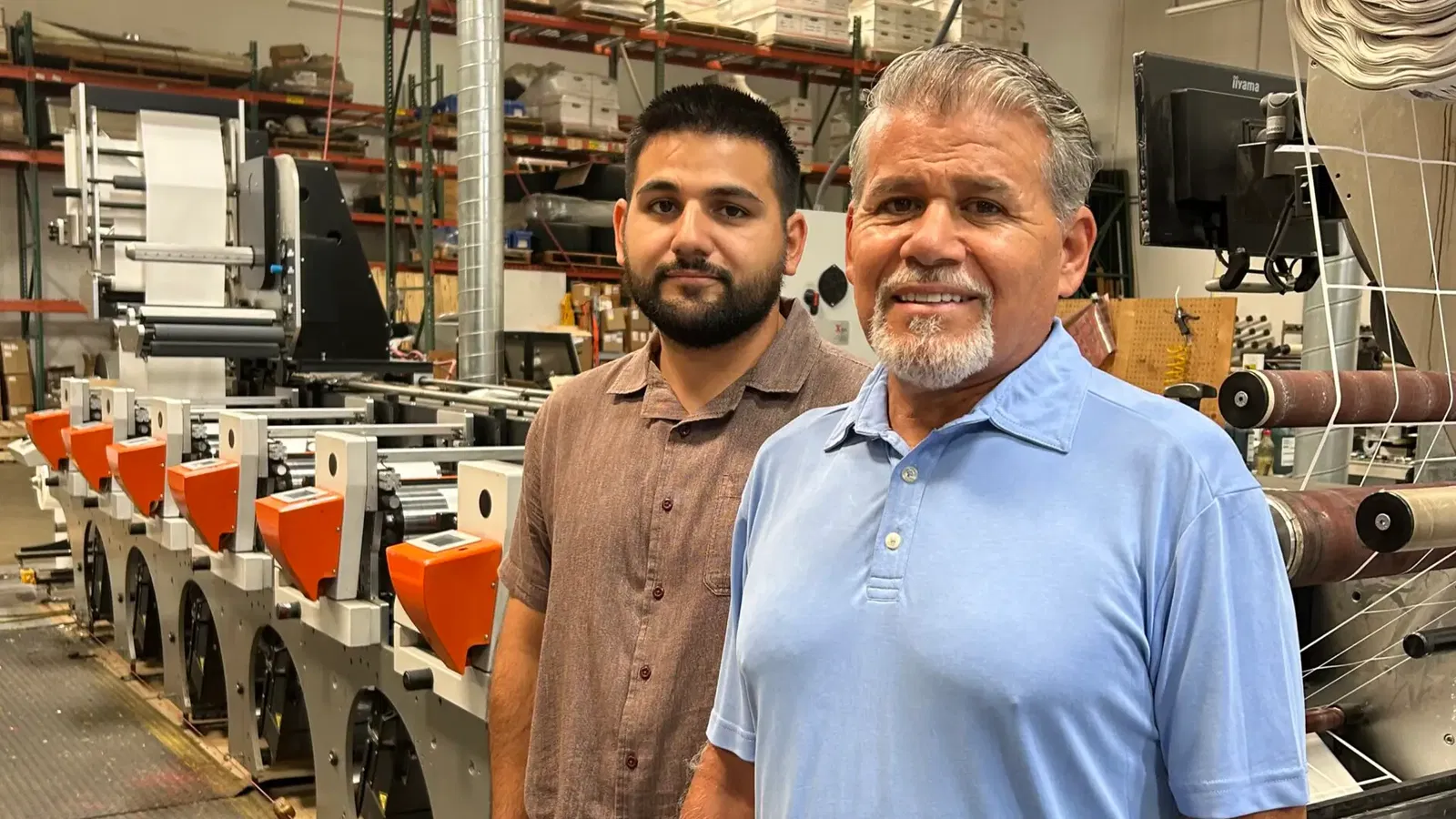

Founded in 2004 by industry veteran George Contreras, Geo Labels built its twenty-year strong reputation on quality, expertise and agility. With over two decades of production experience before starting his own business, Managing Director George’s deep understanding of the industry has been the foundation of the company’s success.

“Customers came to us through word of mouth due to our experience and reputation,” George explained. “Even 20 years later, those same customers rely on us for advice and expertise on developing their labels and branding. We have something that can’t be bought, and that’s the absolute trust of our clients.”

A proud family business, George’s son Luis has been involved with Geo Labels from an early age. Today, Luis is the Chief Officer at Geo Labels, getting more hands-on and involved with the business as he grew up. He said: “Years ago, I remember riding my skateboard around the shop”, before eventually picking up the reins as the next generation of Contreras, with the strong reputation of Geo Labels to uphold.

The challenge: Evolving market demands

As the business grew and scaled, so did the challenges. Like many label converters, Geo Labels found itself grappling with demand for shorter runs, quicker turnarounds, and an increasing need for value-added embellishments. What’s more, the well-documented and industry-wide shortage of skilled press operators posed a significant hurdle to maintaining productivity and quality standards.

“As it becomes more difficult to find skilled press operators in today’s workforce, presses need to be intuitive and fast. Ultimately, it needs to be easier to operate them consistently at their best,” George noted.

Like many of its industry peers, Geo Labels knew that as the label production workforce is stretched to capacity, the answer was in technologies that address these challenges.

The solution: Edale FL3

Enter Edale, known for British engineering excellence on a global stage. Edale’s FL3 press caught the attention of George and his son Luis. After deep-dive discussions with Edale’s North American agent, Mike Golas, the Contreras family found that the FL3’s advanced automation and versatility aligned perfectly with Geo Labels’ evolving needs and chose to invest in the machine.

The FL3 is a label press designed to deliver superior print quality with minimal waste. The FL3 is engineered for high-quality label printing with minimal waste. With a 350mm / 13.7” web width, it serves as an ideal ‘step up’ machine for businesses looking to replace older mechanical presses or expand their capabilities.

The press incorporates key features of the Edale FL range, including servo-driven technology, the renowned UNiPRINT printhead designed for optimal print geometry, and both pre-register and auto-register systems. Its modular design allows for future upgrades, including the addition of EZ Reg and EZ Die systems. Importantly, the FL3 can be configured with water, UV or UV LED ink. The UV LED option offers significant energy savings and maintenance demands compared to traditional mercury lamp-based UV systems – a crucial factor as the industry moves towards LED UV curing as the standard.

These innovations directly address several challenges in label production, such as lengthy setup times, material waste, and the need for highly skilled operators to achieve consistent quality. The press’s open access design, combined with its ease of operation, makes it an excellent choice for businesses dealing with the industry-wide shortage of skilled press operators.

Following the decision to invest, the installation of the Edale FL3 was seamless. Ensuring every member of the team could operate the machine effortlessly and access superb performance out of the gate, Edale conducted full press operator training. Geo Labels reports that even team members with no prior flexo press experience were able to run production jobs independently within just two weeks of training.

“That is actively setting up and running the press, not just babysitting it. The process was much faster than with other presses. This makes it easier to recruit new press operators” said George, while Luis added: “As management of Geo Labels passes to a new generation, I find the easier press operation has also enabled me to focus on other areas of running the company”.

Results: increased efficiency, expanded capabilities

For Geo Labels, the impact was immediate. The ease of operation had ripple effects throughout the business, boosting productivity and efficiency in production, in turn expanding the company’s capabilities.

The press’s advanced tension control and lower printing impression requirements opened up new possibilities, enabling Geo Labels to say ‘yes’ to more client orders. One example Geo Labels found was the ability to consistently print on pre-perforated substrates.

The benefits extend to the company’s bottom line as well. With faster setup times and reduced waste, Geo Labels has seen improvements in both productivity and profitability. The press’s reliability has also been a key factor. “In six years, we have had only one small issue with a worn bearing,” Luis shares. “The issue was diagnosed quickly, and we were up and running again quickly.”

Perhaps most importantly, the FL3 has positioned Geo Labels for future growth. The versatility of the press helps to solidify the label converter’s current capabilities, as well as granting the ability to easily diversify to new markets. This adaptability is crucial in an industry where customer demands can shift rapidly.

Reflecting on their journey with Edale, George and Luis are delighted with the machine’s performance. “We would for sure buy another Edale press,” George affirms. This endorsement speaks volumes about the impact the FL3 has had on the Geo Labels business.

A model for industry adaptation

For other label converters facing similar challenges, Geo Labels’ experience with the Edale FL3 provides invaluable insights. It demonstrates how embracing automation can address multiple issues simultaneously: easing the pressure of operator shortages, improving quality consistency, reducing waste, and opening up exciting new market opportunities.

As the label industry continues to evolve, stories like Geo Labels’ highlight the importance of choosing technology partners who understand the real-world challenges converters face.

Maggie Reed, Edale’s Sales Manager in North America added: “We’re thrilled to partner with Geo Labels and help them meet the evolving needs of the North American label market. This collaboration showcases Edale’s approach at its best – our machines are built around the customer’s specific requirements. We pride ourselves on the fact that our customers never have to fit their operations around our machines; instead, we build them to integrate effortlessly into existing workflows. This approach ensures every machine is refined to meet the customer’s needs.”

Edale’s focus on combining robust engineering with advanced automation features, delivered in a machine suited to each converter’s real-world needs, shows how press manufacturers can deliver solutions that position label printers for future success.

For Geo Labels, the impact was immediate. The ease of operation had ripple effects throughout the business, boosting productivity and efficiency in production, in turn expanding the company’s capabilities.